LUMBER

by Grandpa Cliff

Oct 20, 2005

When a tree is cut down by a lumber company, all of the branches are cut off the trunk. The straight piece of trunk is called a Log. The piece of the tree that is still attached to the roots is called the Stump.

Tree stump Birch logs

After being taken to a lumber mill, the bark can be removed by a

debarker before the log is cut into boards. In the photograh, the

rear log is moving to the left and being turned at the same time.

The debarking machine tears off the bark.

Sometimes the log is cut before the bark is removed (as in the

photograh below at the right edge of the screen).

The drawing below shows two boards that could be cut out of a log. Even though space is shown between the boards, the two boards would actually be touching each other so that no wood is wasted.

SAPWOOD & HEARTWOOD IN LUMBER

Notice the reddish heartwood and lighter sapwood in these boards made from the Redwood tree. Wood is made of xylem (ZIGH-lem) cells.

When a board is cut through a branch that is inside the trunk, the branch may make a round knot in the board. The next photo shows Cedar boards with knots. Notice the heartwood in the center board.

The pattern on the wood depends on the angle of the saw as it cut through the wood.

The lines in the next two photos show the annual rings coming straight up out of the wood.

White Oak Red Oak

In the next two photos, the saw cut through the wood at a different angle to the annual rings,

thereby causing the annual rings to form a different pattern. The wood on the right is elm.

PLYWOOD

Plywood

is made of an odd number of thin layers of softwood or hardwood that are glued together. Each

layer is called a ply.

Plywood

is made of an odd number of thin layers of softwood or hardwood that are glued together. Each

layer is called a ply.

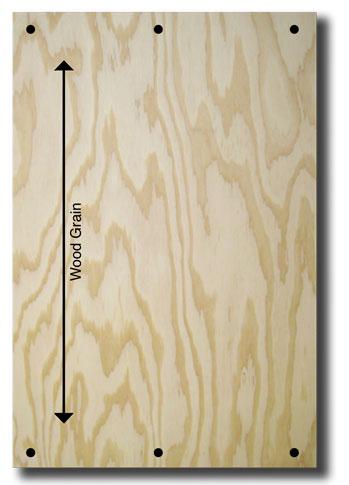

Sheets of plywood for home

construction are 4 ft. wide and 8 ft.

high. The most common thicknesses

are 1/4" to 3/4". The grain usually

runs up a piece of plywood as you

look at a face (see right). The next

layer inside will have the grain run

across the plywood. The third one

will run up the ply, the fourth one

across the ply, and the fifth one will run up the ply. This alternating arrangement of the grain gives the plywood a greater strength, and it is less likely to warp. The kind of glue used will determine whether the plywood can be used outdoors or not.

During house construction, the outside walls and roof are covered

with plywood. Siding and shingles usually cover the plywood so

that you don't see it.

-------------------------------------------------------------------------------------------

Visitors since 30

Dec 2006

Go to the HOME page