9-12

AN EXERCISE IN THINKING

by Grandpa Cliff

Oct 20, 2005. Revised Oct 29, 2011.

We see wood everyday, and we see the patterns and grain in it. This angel is wondering why wood has so many interesting patterns. Scientists are also curious about a lot of things. If you are curious, you should enjoy this thinking exercise.

It is not important for you to learn the facts on this page, but if you learn the general ideas you will better understand and enjoy looking at wood patterns in furniture, wall paneling, wooden bowls, etc. This webpage is an exercise of your mind. Sometimes it is important to learn things, and sometimes it is important just to use your mind trying to picture something that is written. Exercising your mind today will help you figure out more complicated things later. So, let's start exercising.

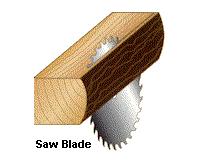

SAWING A LOG

There are two main ways to cut boards from a log. The boards can be:

1) Plain sawn

2) Quarter sawn

In these two boards, you are looking at the small end of each board. The difference in the patterns at the ends of the boards are due to the direction that the saw cut through the annual rings of the log.

A board is made of wood; either sapwood (light colored), heartwood (dark colored), or both on the same board in some sort of pattern.

The dark lines seen in the diagrams above are each an edge of an annual ring. An annual ring consists of two kinds of wood cells; Summer Wood and Spring Wood. Spring Wood is made during a time when there is more rain and a great deal of growth. That makes the cells larger. They reflect more light and therefore look lighter. The dark rather narrow lines that show the edges of each layer are the Summer Wood made of smaller cells.

PLAIN SAWN LUMBER

Look at the top of the Plain Sawn diagram above. The top line of an annual ring touches the upper face of the board in two places. Let's pretend that the board was cut from center heartwood (darker wood), but that the annual ring above where the board was cut was the first sapwood layer. That would mean that the two corners in the diagram above would be made of lighter sapwood.

If the plain sawn board above is the same board as the right board in the photo at the left, then you can understand why most of the board is made of dark wood, although the sides would be made of the lighter-colored sapwood. The part of the leftmost board which we can see is made entirely of sapwood.

The log at the right has been plain sawn. This type of sawing wastes the least wood. When the bark is sawn off each side, just a little sapwood will be attached to the piece removed. (As you can tell, the log has been sawn into very thick pieces, much thicker than the average board.)

Plain sawn cuts also take the least amount of time of the various kinds of cuts that could be made. Saving wood and saving time means that the mill will make more money, or can charge less for the wood that they sell.

Plain sawn Oak wood shows an interesting pattern to the annual rings.

The

Plain sawn Oak wood shows an interesting pattern to the annual rings.

The

dark lines are the dark lines of annual rings. The angle of the cut makes

them wider than expected. If a log was cut straight across from one side to

the other, the annual rings would be almost circular in shape. When looking

at furniture made with this kind of cut, your eye is drawn to the pattern instead of the workmanship of the furniture. Furniture makers usually want you to look at the furniture they made, so they prefer the quarter sawn grain. Also, the quarter sawn wood is less likely to warp, crack, bow, or change its shape.

QUARTER SAWN LUMBER

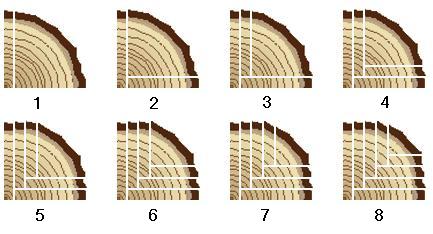

The term quarter sawn refers to the fact that the boards are cut from a quarter of a log instead of a whole log. To get a quarter log, a whole log is first cut in half along its length. Then, each half is cut in half again. The log has then been cut into four quarters. Each quarter is then sawed as in the following diagrams. In the cuts below, the saw blade remains vertical at all times, so the log has to be rotated (turned) 90o after every cut. This extra amount of time causes quarter sawn lumber to be more expensive. However, it is better lumber.

The next diagrams show what happens

to the wood in each step.

-----------------------------------------------------------------------------------

1. Cut the board vertically.

Remove the loose board.

Remove the loose board.

Rotate

log 90o counter-clockwise; cut board.  Remove loose board.

Remove loose board.

Rotate

log 90o clockwise, then cut board.  Keep

repeating till all boards are cut.

Keep

repeating till all boards are cut.

-----------------------------------------------------------------------------------

Now that you know the procedure, go back to the diagrams numbered 1-8. Try to picture which way the quarter log is turned each time and which side the board is cut from. This is a good mental exercise. If you can't do it, reread this section (Quarter Sawn Lumber) again. If you still can't do it, come back and try again another day.

The advantage of quarter sawn lumber is that the annual rings go almost straight from one face of the board to the other (the annual rings are almost perpendicular to the face of the board).

This means that the boards will warp, twist, split, swell, and shrink less than in plain sawn wood. Here are some examples of what the top surface of quarter sawn wood would look like.

Maple Poplar White Oak Red Oak

These pieces of wood are all quarter sawn and show the annual rings as lines in the wood. The appearance of the dark part of the annual rings (the Summer wood) is generally referred to as the grain. The Maple, Poplar, and White Oak photos all show a light sapwood and darker heartwood. The grain is made of lines that are almost parallel to each other.

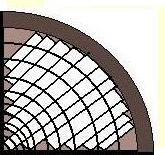

AN ALTERNATE WAY OF QUARTER SAWING

The white area on this diagram shows 11 boards that can be cut out of this

quarter log. Inside the bark (the outer dark ring), there is much more

wood wasted (colored brown) in this technique of quarter sawing the lumber

than in the method of quarter sawing

discussed above. Because there is more wood wasted here, this type of quarter

sawn lumber costs more.

The white area on this diagram shows 11 boards that can be cut out of this

quarter log. Inside the bark (the outer dark ring), there is much more

wood wasted (colored brown) in this technique of quarter sawing the lumber

than in the method of quarter sawing

discussed above. Because there is more wood wasted here, this type of quarter

sawn lumber costs more.

By looking at wood grains and patterns, can you now tell plain sawn wood from quarter sawn wood? But, more important, were you able to picture in your mind the things that were described?

-------------------------------------------------------------------------------------------

Another thinker.

Visitors since 30

Dec 2006

Go to the HOME page